Suggestions

Some of these products are already licensed exclusively for certain territories and may not be available. Many of these products represent multi-billion dollar markets in the U.S. alone, and those greater than billion dollar markets are shown with an asterisk.

Slate-like roof tiles

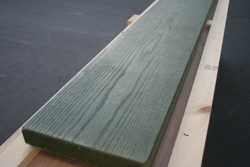

*Wood-like decking

*Structurally insulated housing panels

*Utility poles & crossarms

*Railway sleepers

*House siding & trim

Highway sound barriers

Agricultural stakes

*Fencing

*Roofing tiles & panels

Marine pilings

*Doors

Scaffolding, non-catastrophic failure

Window frames

Sign Posts

Fireplace mantles

Picture frames

Dog houses

Crypts

Architectural interior & exterior parts

Columns

Pallet blocks

Large signage letters

*Molding

Flower pots

Mail boxes

Garage doors

Park benches

Landscape timbers

Planters

Animal stall walls

Animal feed troughs

- Low cost products, due to high filler loading and foaming

- Dimensionally stable

- Corrosion resistant

- Waterproof

- Can be fire-resistant to fireproof

- Can have high impact resistance

- Resistant to termites, insects, sea worms

- Rot-resistant

- Holds nails and screws like wood

- Easily machined

- Can be lightweight or very dense

- Thermally and acoustically insulating

- Can be painted, stained or pigmented

- Can reduce heavy metals leaching to safe tolerances

- Can be stiffer and stronger than "plastic woods"

- Will not warp, splinter, blister or soften

Test results on several synthetic lumber products, with four different fillers. This matrix contains randomly chosen products to give an idea of the mechanical properties that can be obtained. The mechanical properties vary considerably depending upon addition of fibers and/or fabrics, filler percent, other chemical additives, and the density.

|

Coal Ash

|

Mineral Filler |

Coal Ash |

Granite Dust |

Ground Waste Bottle Glass |

How Processed: |

Continuously Extruded & Formed

|

Continuously Extruded & Formed |

Hand Mixed & Cast with Continuous Carbon Fabric Sheath |

Hand Mixed & Hand Cast |

Hand Mixed & Hand Cast |

Filler/Waste Content |

65% |

70% |

40% |

75% |

70% |

Product Density, lb/cu ft |

55 |

39 |

46 |

68 |

56 |

Flexural Strength, psi

|

2500 |

1884 |

5084 |

2048 |

1797 |

Flexural Stiffness, ksi

|

500 |

312 |

998 |

263 |

300 |